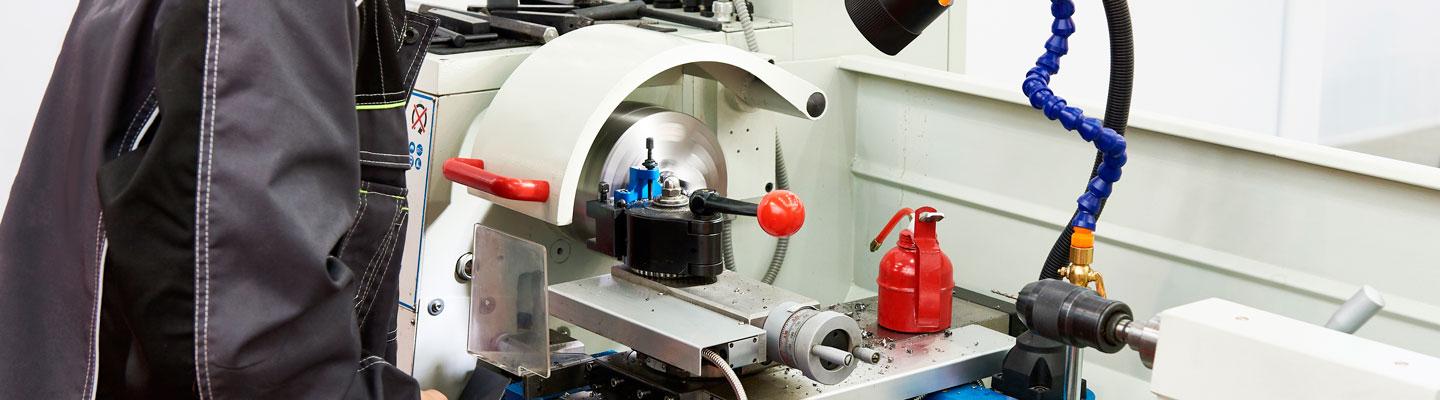

Machine guards or barriers between the operator and dangerous parts are one of the most common strategies that manufacturers use to make their tools safer.

Types of machine safeguarding osha.

There are five 5 general types of machine safeguards that can be used to protect workers and personnel in the immediate vicinity of machinery.

There are several different types of machine guards.

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks.

Osha machine guarding e tool rev 3 31 17 the information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication.

Safety is paramount and safety guards on machinery can prevent amputations lacerations and other preventable injuries.

Must prevent workers from lubricating a machine without removing the safeguard.

Primary safeguarding as used in this publication includes control meth ods that protect e g prevent employee contact with hazardous machine areas employees from machine hazards through effective machine guard ing techniques.

Types of machine guards.

No representation is made that the information or references are complete or remain current.

The following are all machine safeguarding requirements except.

Types of safeguarding.

Safeguards are essential for protecting workers from needless and preventable injuries.

Guards are materials that keep workers from having direct contact with moving parts and other dangerous areas.

Safety guarding protects people from dangerous machine parts.

Methods of machine safeguarding there are many ways to safeguard machines.

Examples of guarding methods are barrier guards two hand tripping devices electronic safety devices etc.

Install guarding on any accessible portions of a machine because it will reduce the chance that an injury could occur.

Basics of machine safeguarding crushed hands and arms severed fingers blindness the list of possible machinery related injuries is as long as it is horrifying.

There seem to be as many hazards created by moving machine parts as there are types of machines.

Any part of a machine which while in operation can cause a hazard.